Compounds & Master Batches

Introduction:

We are also manufacturing all type of Breathable PE compounds, Master batches, Special Compounds with carrier resin PE & PP. Our quality technology for the manufacture of White Master batches. The process and equipment allows the incorporation of very high levels of white Titanium Dioxide Master batches.

Our Brand Specialty:

Special white designed for specific end use applications include UV stabilized grades, Grades with specific Color tones.

Breathable white Master batch grades and food contact acceptable grades also.

Applications:

- Packaging Films

- Injection Moulding Products

- Blow Moulding Products

- Consumer & House Hold

- Automotive

- Electrical Appliances

- Fibers

- Agriculture & Horticulture

Introduction:

A laminated fabric is available with two or more layer construction with a PE film laminated with Non-woven fabrics.

Laminated fabric is used for manufacturing a wide variety of Medical Back sheets, protective apparels, surgical gowns, Drapes, Mask, Gloves, Permeable house wrap & Waterproof Apparels.

Specification:

Fabric Weight (GSM) : 10 – 40 GSM

Width : 165 – 2200mm

Types : Fully & Partial Laminated (Hot Melt Lamination)

Introduction:

Thermoplastic elastomer (TPE) films that are permeable to water vapor, or “breathable,” are finding increasing use in the medical industry.1–3 To meet this demand, a range of such films with chemistries based on ether-type soft segments and amide, urethane, or ester hard segments have been developed. They typically demonstrate the characteristic properties of ether-based TPEs—processability, elasticity, permeability, and strength.

TPE Film can be designed for lamination to technical textile fabrics. The TPE film serves as a barrier membrane to dust or bio-hazards such as blood-borne pathogens, while still allowing perspiration to escape—a process referred to as a water-vapor transmission rate (WVTR).

It is suitable for manufacturing a wide variety of protective apparel, surgical gowns, Drapes, Mask, Gloves, Permeable house wrap & Waterproof Apparel.

Specification:

Film Weight (GSM) : 13 – 40 GSM

Width : 200 – 2100mm

Introduction:

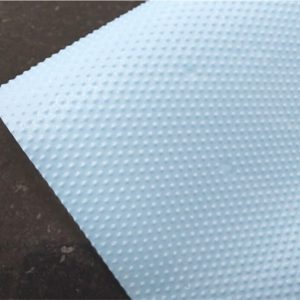

Non Breathable film is Non Porous structures. Non Breathable film restricts liquid flow, Air flow and water vapour. This film is used as a Backsheets for manufacturing baby diapers, adult diapers, Sanitary napkins,medical back-sheets, Medical Gowns, PPEs and various personal hygiene disposable products.

The main Benefit of Non Breathable Films is

i. Liquid Control

ii. Softy touch

Specification:

Film Weight (GSM) : 10 – 40 GSM

Width : 70 – 2200mm

Printed/Color : Up to 6 Color

Embossed : Micro & Deep Embossed